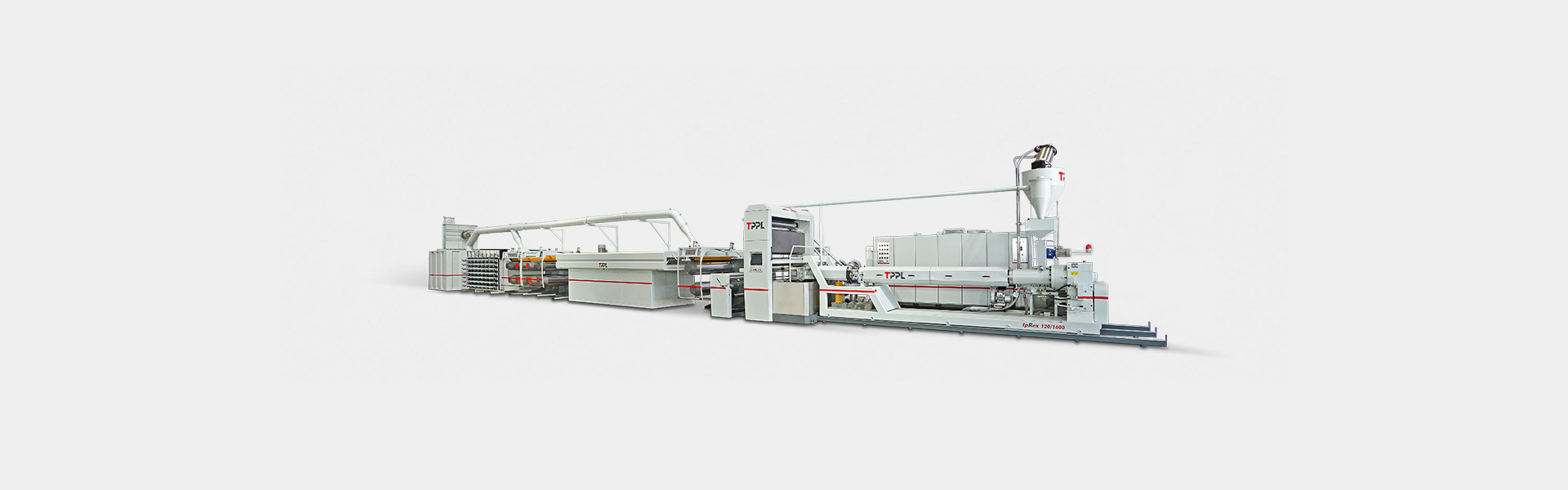

Tape Stretching Lines

TPPL offers complete range of Tape Extrusion Lines for High Quality Universal processing of PP / HDPE Tapes for a wide range of Applications such as Block bottom bags, FIBC / Jumbo Fabrics, Woven Bags, Geo and Agro Textiles, Carpet Backing, Fibrillated Artificial Grass, Wrapping Fabrics, Tarpaulins, Ropes, Twines and many more.

Excellent tape/yarn quality at high output for outstanding efficiency of the line. Latest design and advanced process technology allows to produce tapes with exceptionally high strength (weight to strength ratio) at maximum speeds with minimum energy consumption.

Our High-Speed Tape Stretching Lines are of premium Quality with one Level-Up Technology along with Cost Effectiveness. They have excellent Price - Performance Ratio (Best in Class) and meets all latest International Standards.

Innovative Extrusion

Energy Efficient Extrusion Unit with Inline Mixer, Performance screw, Continuous filtering System and Precise Die.

Best Melt Quality

Melt / Gear Pump delivers Pulsation free, Accurate volume per rpm.

Sleek Design

Stretching & Annealing Godet Unit with up to 450mm Diameter with optional Safety Guard System.

Best in Class

World Class Extruder Gear Box that performs most efficiently with lowest transmission and energy losses.

Perfect Winding

Inverter driven Winders with High-Speed Operation ensures Lowest Power Consumption.

Smart Operating

Full Touch Controlled / Enabled Unit with Single - Point centralized Access. Easy to Operate, Real time display of Energy consumption, Production, Alarms and many more.

- tpRex

Our tpRex series Tape Lines are popular for great value for money factor and Lowest Capital Investment per kg production capacity. It is well designed to extrude PP or HDPE tapes for high performance applications at lowest cost.

Advantages

- High Production speed up to 500 meters/min

- High Melting capacity up to 650 kg/h

- Universal Processing of PP and HDPE

- Excellent Tape Quality with ease of to produce lightweight tapes

- High Tenacity Tapes with Low Denier Variation

- Lower Energy Consumption with Simple Maintenance

Technical Specifications

| MODEL | tpRex 90 | tpRex 105 | tpRex 120 |

|---|---|---|---|

| Screw diameter (mm) | 90 | 105 | 120 |

| Maximum melt capacity (kg/hr) * | 350 | 450 | 650 |

| Working width (mm) | 1000 to 1800 | ||

| Line Speed Mechanical - max (m/min) | Up to 500 | ||

| Optional | Hot Plate – Orientation Unit | ||

| Flat Tape Fibrillation Unit | |||

| Gravimetric Dosing and Mixing Unit | |||

| Additional Hot / Cold Godet Roller / Stretching Unit | |||

| Online Film Thickness Measuring / Control Unit | |||

| Continuous Filter Belt Type Screen Changer | |||

* Depending on quality of raw material and additives