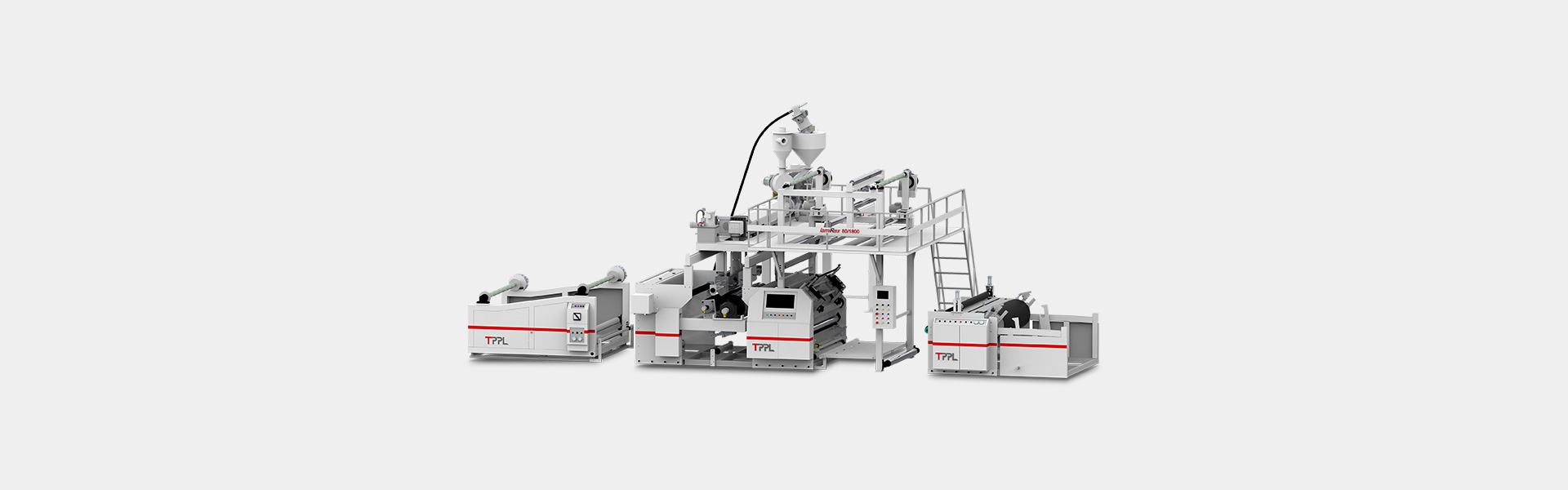

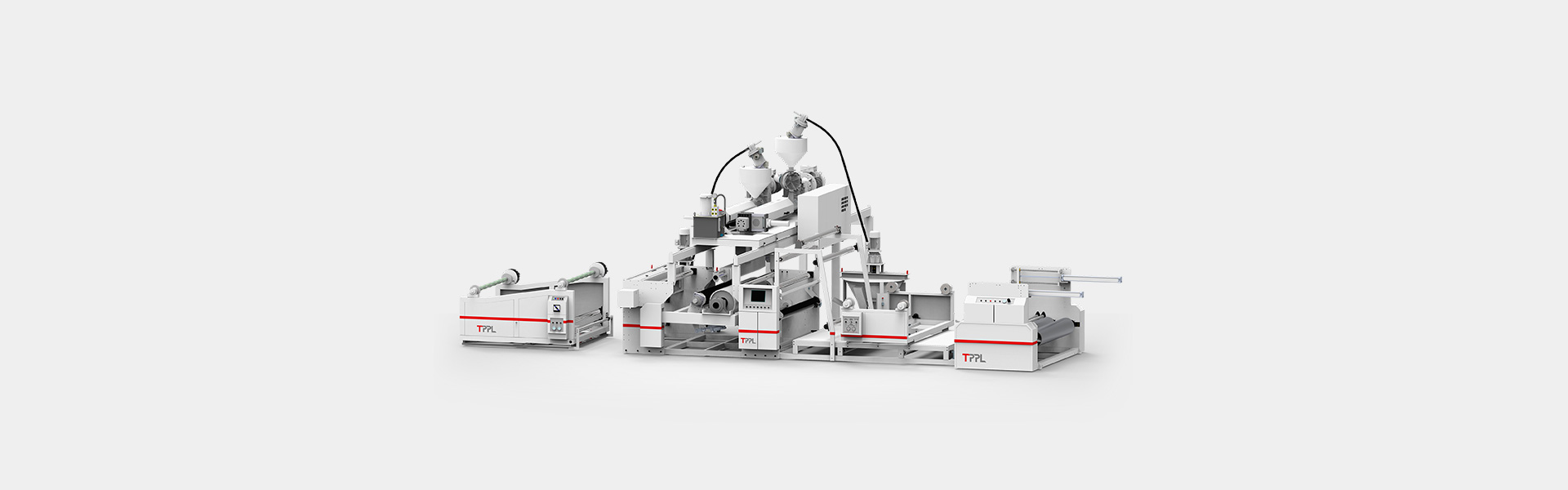

Extrusion Coating & Lamination Lines

A big Amount of woven sacks is produced with coating, because coatd sacks provide better protection of the contents from dust and moidture. also, gives better printability.

Our Next Generation lamiRex series offers high-level coating and laminating lines designed for the needs of woven fabric coating, the machine offers outstanding flexibility ad allows for coating or sandwich-laminating of a wide range of substrates such as woven fabric of PP or PE, paper, BOPP film and nonwoven.Because of its double layout, tubular fabrics are coated on both sides in one go.

Best Workmanship, innovative Technology & Modular design allows with maximum flexibility, meeting the most sophisticated demands of Modern Packaging.

upto 200 m/min

upto 4000 mm

upto 600 kg/hr

Strong Coating Adhesion

Uniform Coating

Auto Changeover

Lower Energy Consumption

Operator Friendly

High Speed Working

Nonstop Operation

Most Efficient Operation

Simple Maintenance

- lamiRex BX

- lamiRex TX

- lamiRex WX

- lamiRex CX

Extrusion Coating Lines for Bags / Non-Woven / Paper / Polyester / Alu Foil

Most Popular series with flexibility of multiple selection of substrates. These series models are mainly use for different type of bags made from woven/nonwoven fabrics with or without sandwich lamiantion of BOPP, Paper, Foil etc...these kinds of bags to pack Fertiliser, Rice, cattle feed, pulses and many more.. Paper coating model is used to do coating on paper for different end applications.

| Model | lamiRex 900 BX |

lamiRex 1200 BX |

lamiRex 1500 BX |

lamiRex 1650 BX |

lamiRex 1800 BX |

|

|---|---|---|---|---|---|---|

| Screw Diameter (mm) | 75 | 75 | 75 | 75 | 75 | |

| Extrunder. melt capacity* PP/PE(Max) - Kg/Hr |

upto 180 | |||||

| Die Working width - mm | 900 | 1200 | 1500 | 1650 | 1800 | |

| Coating width-mm (min/max) | 350-720 | 600-1050 | 750-1350 | 800-1500 | 1000-1650 | |

| Coating Thickness* (min/max) - micron | 10-90 | |||||

| Line speed *mechanical (max.) - meter/min | upto 150 | |||||

Tandem Extrusion Coating Liens

TX series is Tandem sysytem lines, where coating on both sides of substrate at single pass. Higher Production makes these models in demand. These are widely used for long run, larger quantity jobs. Tandem lines are used for coating on almost all kind of substrates like... woven/nonwoven fabrics with or without sandwich lamination of BOPP, Paper,etc...

| Model | lamiRex 900 TX |

lamiRex 1650 TX |

lamiRex 2100 TX |

lamiRex 2700 TX |

|---|---|---|---|---|

| Screw Diameter (mm) | 75+75 | 75+75 | 80+80 | 80+80 |

| Extrunder. melt capacity* PP/PE(Max) - Kg/Hr |

up to 300 (combined} |

up to 350 (combined} |

up to 400 (combined} |

up to 400 (combined} |

| Die Working width - mm | 900+900 | 1650+1650 | 2100+2100 | 2700+2700 |

| Coating width- mm(min/max) | 350-750 | 800-1500 | 1200-1900 | 1700-2500 |

| Coating Thickness*(min/max) - micron | 20-100 | |||

| Line speed* mechanical (max.) - meter/min | upto 150 | |||

Extrusion Coating Lines for Tarpaulin / Wide fabric / FIBC - Jumbo

These series of Machines are for Coating on Wide substrates like - Tarpaulins, Agri textiles, Geo fabrics, FIBC/Jumbo fabrics etc.. These are Special and wide width application machines with higher melting Extrunder. Options of Sandwich and Tandem available in all models.

| Model | lamiRex 2100 WX |

lamiRex 2300 WX |

lamiRex 2700 WX |

lamiRex 3900 WX |

lamiRex 4300 WX |

|---|---|---|---|---|---|

| Screw Diameter (mm) | 80 | 80 | 90 | 90 | 105 |

| Extrunder melt capacity* PP/PE(Max) - Kg/Hr |

up to 200 | up to 200 | up to 300 | up to 350 | up to 400 |

| Die Working width - mm | 2100 | 2300 | 2700 | 3900 | 4300 |

| Coating - Flat fabric - mm | 1200-1900 | 1300-2100 | 1600-2500 | 3000-3700 | 3400-4100 |

| Coating Thickness* (min/max) - micron | 20-100 | ||||

| Line speed* mechanical (max.) - meter/min | upto 120 | ||||

Multi Extrusion Coating Lines - CoEx / TriEx

Mutli Layer/wall extrusion is most trending and emerging in current time.These CX series of machines are used for mainly two reasons - To use Reprocessed and Filler in increased quantity as a sandwich layer and To use inner and outer layer for different conmbination of colour and material as per reqirement.it is mainly multi extrunding using common/single coating Die.

| Model | lamiRex 2100 CX |

lamiRex 2700 CX |

lamiRex 2100 CXTD |

lamiRex 2700 CXTD |

|---|---|---|---|---|

| Screw Diameter (mm) | 65+80 | 75+90 | 65+80 65+80 |

75+90 75+90 |

| Extrunder melt capacity* PP/PE(Max) - Kg/Hr |

up to 300 | up to 450 | up to 600 | up to 800 |

| Die Working width - mm | 2100 | 2700 | 2100-2100 | 2700-2700 |

| Coating width-mm (min/max) | 1100-1900 | 1700-2500 | 1100-1900 | 1700-2500 |

| Coating Thickness* (min/max) - micron | 20-100 | |||

| Line speed *mechanical (max.) - meter/min | upto 120 | |||